Module Cleaning based on Informed Decision in Solar PV Plant

The Solar PV Plants module cleaning is one of the key activities under Operation & Maintenance services. The common belief is that more module cleaning can lead to more generation and thereby more revenue. The way ground water is getting depleted due to this way of module cleaning cannot be considered as a sustainable practice. So, the time has come to undertake module cleaning based on informed decision by applying logic and not just as per the contract requirement.

As per the scope of this article the author has considered only the ground mounted MW scale projects and cleaning with water only which is the most prevalent way of module cleaning in India. It has been seen that the contracts are signed based on Service Level Agreement (SLA) of undertaking 02 (two) cycles of module cleaning per month and in some cases 18 cycles, taking 01 cycle cleaning in three monsoon months.

We need to understand here that only soft water is recommended to use for module cleaning, and this is a finite resource although we know that water is a renewable resource. The reasons behind considering water as finite resource are as below: –

- The rate of withdrawal and recharging are not matching

- A solar plant may have a life of 25 years or more, but water availability may not last till that period

- We are mostly using the water without any arrangement for recycling

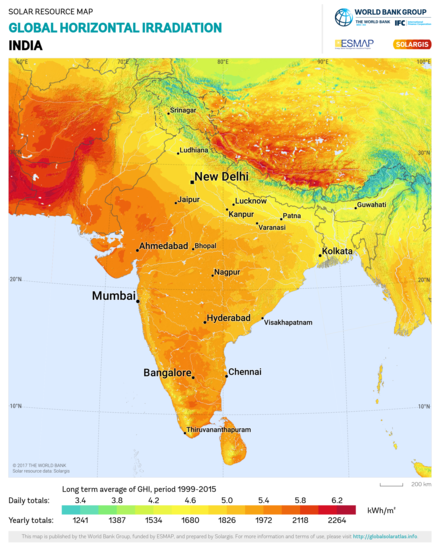

Also, some of the most potential areas with high irradiation for Solar PV Power Plants are arid or semi-arid areas including hot or cold deserts and these places have acute water scarcity, so, its judicious usages are must to consider. Moreover, any water conserved can be used for some other useful purposes such as Agriculture or domestic uses.

Now, Let’s check the effect of module cleaning on generation.

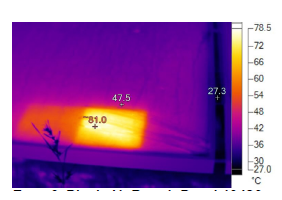

The module cleaning should be done based on the dust concentration and not merely as per the contract bindings. Time should be devoted to measure soiling ratio, string current and inverter performance analysis to arrive at critical areas where performance is affected and to check whether it is attributed to deficiencies in module cleaning or not.

The methods to understand the dust concentration or actual requirement of module cleaning are: –

- If any drop in Performance Ratio (PR) value in no Break Down conditions

- Usage of technologies to have soiling monitoring system.

According to the IEC61724-1:2017 standard for photovoltaic system performance monitoring, a PV plant should have as many soiling monitors as there are pyranometers for irradiance. However, soiling is a rather different phenomenon to radiation, and is also very site-specific. Where you normally expect the same average global horizontal irradiation (GHI) value for all the pyranometers across a solar plant over a day, this is not necessarily true for soiling. If the wind always blows from the North, one would expect more soiling (and thus a different cleaning interval policy) at the Northern side of that plant. When the wind direction changes over seasons, this pattern could shift during the year.

So, time has come to respond to the informed decision for module cleaning and not only on the contractual obligations.

We would like to invite views from Solar Experts, Solar O&M operators, Solar Plant Engineers, Owners and Developers of Solar Power plants about what they think should be an ideal way to save resources, maximize generation and do module cleaning based on informed decisions.

Pingback: Water Conservation in Solar PV Plants: Need and Possibilities - SolarPost